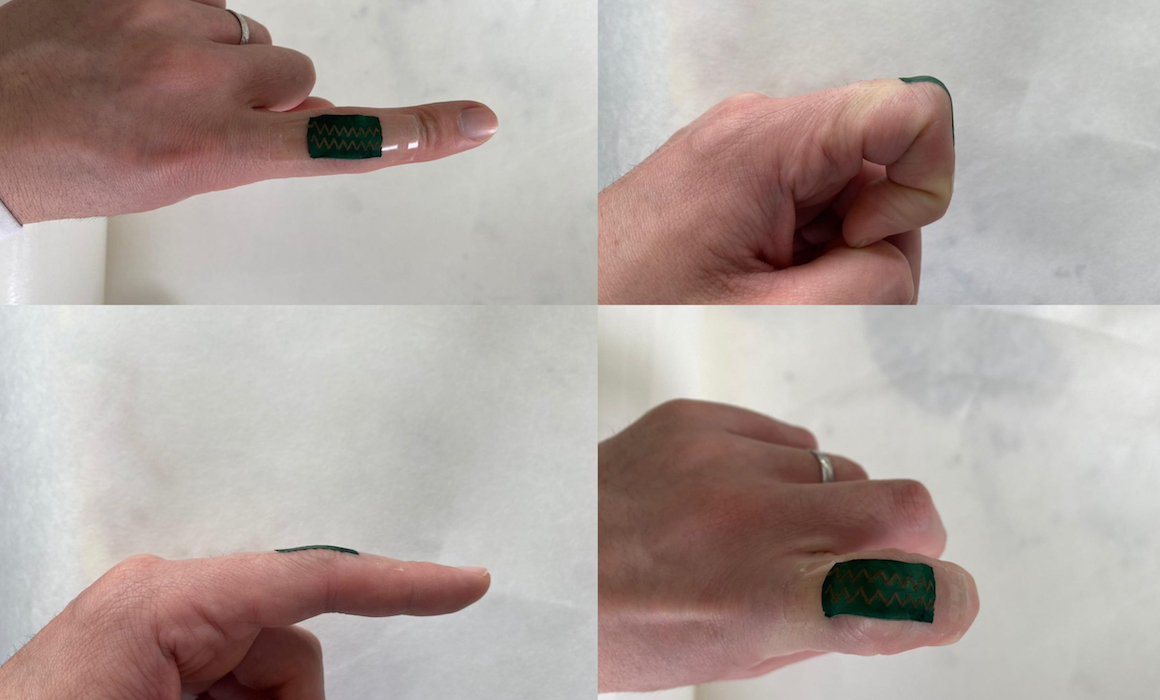

Technion scientists have produced a highly stretchable electronic material and a wearable sensor capable of precisely identifying bending and twisting motion. Together, they form an electronic “skin” capable of recognizing the range of movement human joints normally make, with up to half a degree precision.

This breakthrough is the result of collaborative work between researchers from the Laboratory for Nanomaterial-Based Devices, headed by Professor Hossam Haick from the Wolfson Faculty of Chemical Engineering. The results were recently published in Advanced Materials and featured on the journal’s cover.

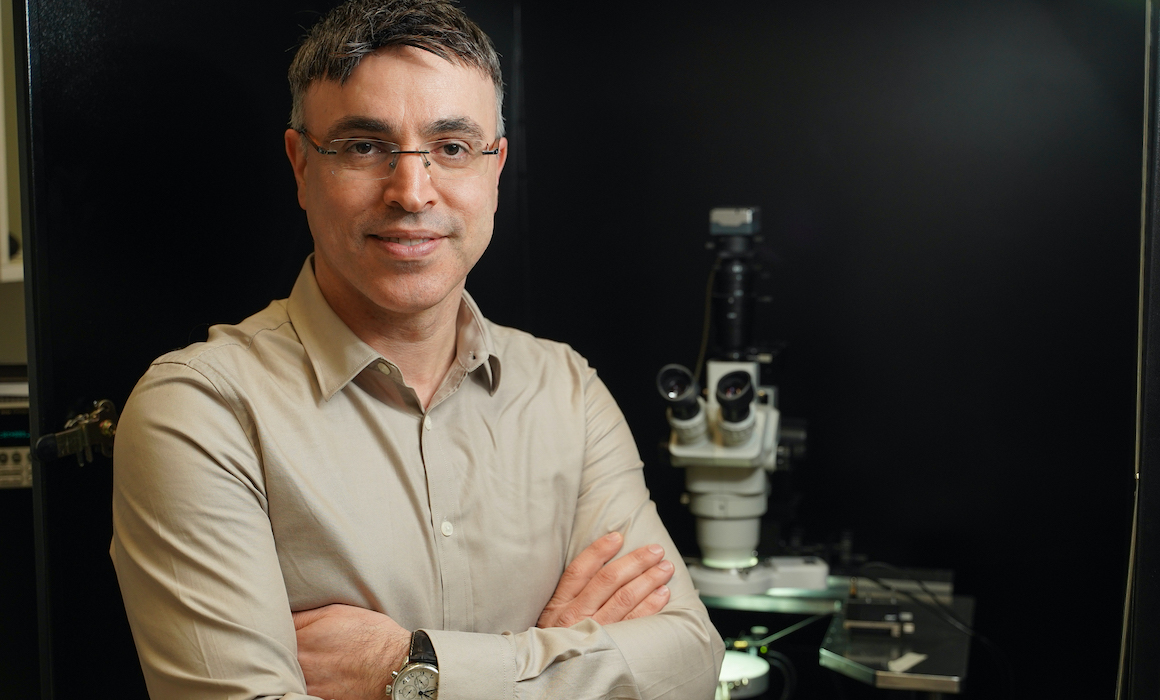

Professor Hossam Haick

Prof. Haick’s lab is focused on wearable devices for various uses. The wearable motion sensors on the market today can recognize bending movement, but not twisting. Existing twisting sensors, on the other hand, are large and cumbersome. Ph.D. candidate Yehu David Horev and postdoctoral fellow Dr. Arnab Maity found a way to form a composite material that was flexible, stretchable, breathable, and biocompatible, and that did not change its electrical properties when stretched. Dr. Maity created an algorithm capable of mapping bending and twisting motion – the nature of the movement, its speed, and its angle. The novel sensor is durable and lightweight, allowing it to be worn on the human body for prolonged periods.

Technion scientists have created an electronic skin that can recognize the range of movement human joints normally make, with up to half a degree precision.

“This sensor has many possible applications,” Prof. Haick stated. “It can be used in early disease diagnosis, alerting doctors of any changes in breathing patterns, and motor system disorders such as Parkinson’s disease. It can be used to assist patients’ motor recovery and be integrated into prosthetic limbs. In robotics, the feedback it provides is crucial for precise motion. In industrial uses, such sensors are necessary in monitoring systems, putting them at the core of the fourth industrial revolution.”

“Electrically conductive polymers are usually quite brittle,” explained Mr. Yehu about the challenge the group had overcome. “To solve this, we created a composite material that is a little like fabric: the individual polymer ‘threads’ cannot withstand the strain on the material, but their movement relative to each other lets it stretch without breaking. It is not too different from what lends stretch to t-shirts. This allows the conductive polymer to withstand extreme mechanical conditions without losing its electrical properties.”

Crucially, this sensor is able to be effective while still being inexpensive to produce. This allows the sensor to potentially benefit anyone, regardless of location or socioeconomic status.