Pictured Above / Prof. Mirela Ben-Chen

To anyone who’s seen videos of robotic arms in motion, lifting and interlocking parts in construction, it’s clear that computer science has everyday applications. In fact, the use of increasingly sophisticated robots in architectural design and manufacturing is seen as a major technological trend in the construction industry.

But while complex architectural projects are often planned on computers, they are executed using construction methods that have remained virtually unchanged for decades. Human intervention is usually necessary, especially when architectural planning is based on complex spatial systems such as thin, doubly curved surfaces, known as shells.

Now a research group from the Henry and Marilyn Taub Faculty of Computer Science has developed an algorithm that streamlines and automates architectural forms.

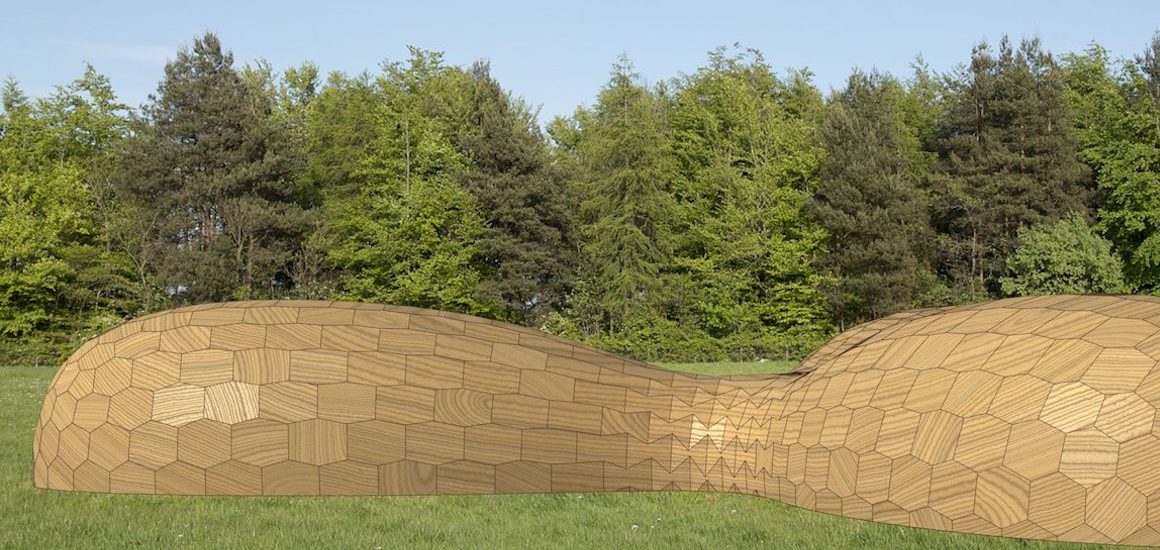

Computer rendered image of one of the segmented 3D models computed by the new algorithm

The process began with a request from an architect seeking automated solutions to robotic manufacturing needs for complex surfaces. Led by Mirela Ben-Chen of the Center for Graphics and Geometric Computing together with Professor Amir Vaxman of Utrecht University, the team created an algorithm that inputs complex and diverse doubly curved surfaces and computes its segmentation into flat panels. These ‘planar’ panels can be assembled from cardboard, a first step toward robotically manufacturing shells from timber.

The algorithm “can take complex surfaces and break them down into small segments, hexagons, in a way that increases the surface’s mechanical advantages,” Prof. Ben-Chen explained. Moreover, it could usher in numerous advantages such as reduced costs and construction time, and lessen the environmental impacts of the building process.

“It’s important to recognize that industrial robotic manufacturing is not a technological whim,” said Prof. Ben-Chen. “Ultimately, we hope that our research will lead to the development of a system that can compute and manufacture building segments through automation, so that they can be assembled on-site without detracting from or compromising architectural or structural complexity.”